Tensar® TriAx® (TX) Geogrids

- Triaxial geogrid designed for stabilisation of aggregates and soils

- Advanced durable material for improvement of roads, rail and trafficked areas

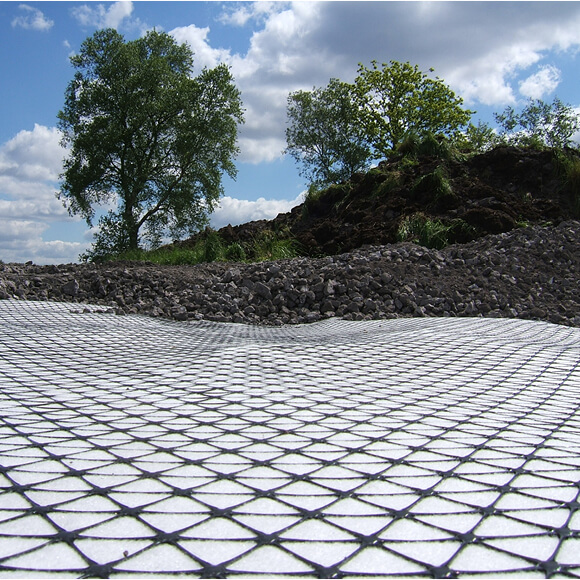

- Hexagonal structure with triangular apertures for high load absorption and distribution

- Stiff structure, high rib profile and strong junctions for optimum aggregate interlock and confinement

Tensar® TriAx® geogrid was the first product to be manufactured specifically for the stabilisation of aggregates. Tensar's triaxial geogrids are designed to optimise interlock and confinement, both essential for the control of particle movement, resulting in a stronger, stiffer aggregate layer with increased load spreading capacity and deformation resistance.

With applications in road foundations, pavement layers, rail trackbed and other trafficked areas, incorporating a triaxial geogrid can result in aggregate savings of up to 50%, with the associated benefits of reducing cost, transportation, construction time and emissions.

Tensar Triaxial geogrids is available in grades: TX150, TX160, TX170, and TX190L. TX5 and TX7 grades are also available as a component in full-depth pavement designs.